QuiiN

Precise multi - ion Implantation for discovering full spectrum of New Materials Possibilities

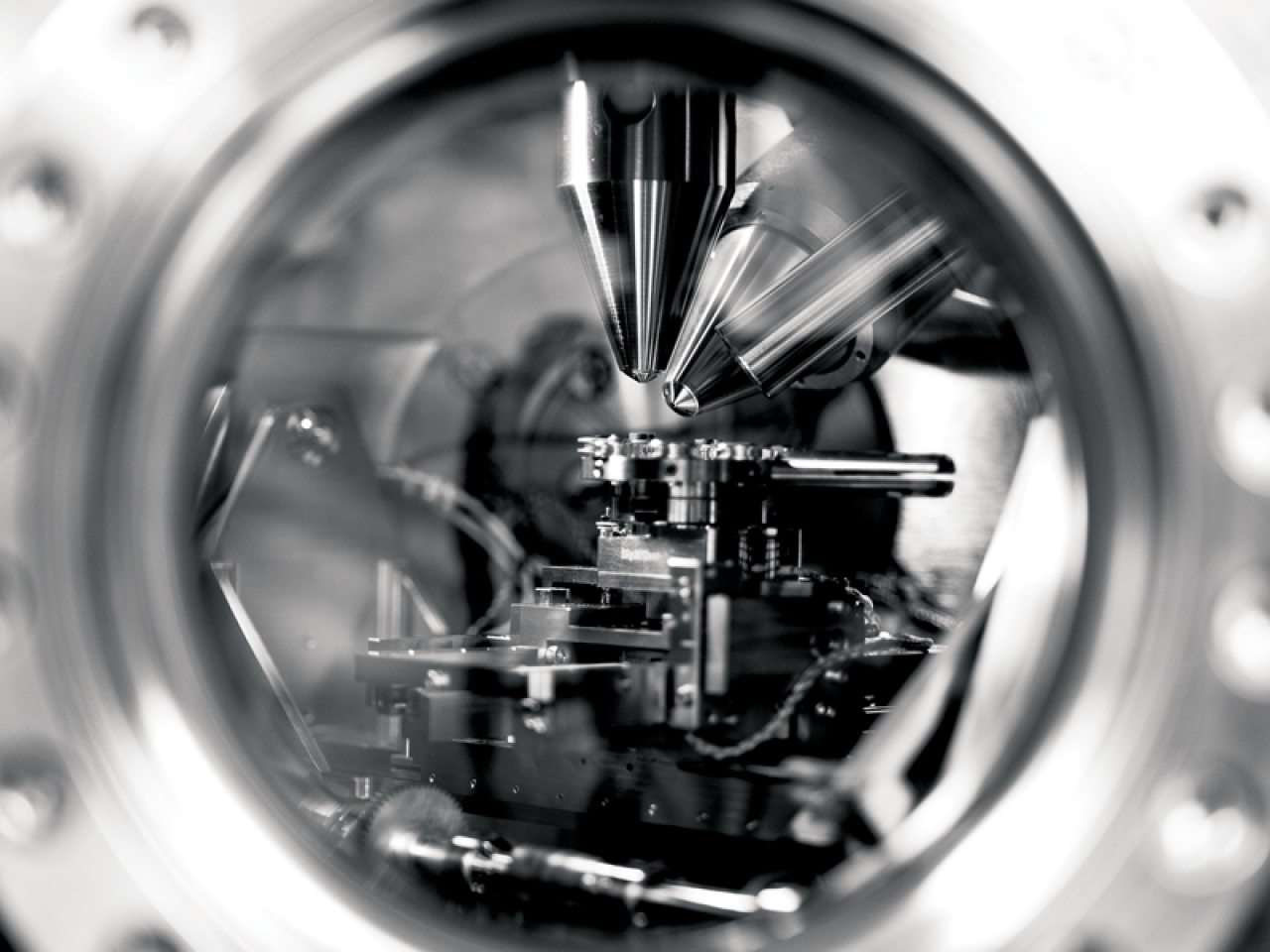

ORSAY PHYSICS QuiiN (Quantum Ion Implanter at Nanoscale) is a versatile ion beam system designed for implantation applications. This last generation of platforms is crucial for the next phase of quantum computing revolution, which requires precisely placed ions within material structures.

QuiiN combines an electrostatic SEM for region localization and one of our two new FIB columns designed for implantation. The Veloce column allows the implantation of specific isotopes of gold, germanium, or silicon using a Wien filter. The iVeloce column, also equipped with a Wien filter, enables the use of various gases such as nitrogen, argon, oxygen, helium, xenon, or gas mixtures like CO2. Both columns feature a new beam current meter for precise dose implantation.

Additionally, QuiiN includes an in-situ heating stage, FurnaSEM 1000, which quickly heats the sample to over 950°C and maintains this temperature, enabling in-situ annealing during irradiation. The in-chamber SE detector is optimized for high-quality imaging, allowing observation of sensitive samples without damage, even at low current.

Powered by ORSAY PHYSICS Pegasus, a modular and customizable graphical user interface, QuiiN enables users to design their own implantation experiments. Pegasus offers unique milling strategies based on points, reducing beam impact and improving milling or deposition effectiveness. All control parameters are integrated into the API, allowing users to script or integrate any part of the machine.

|

Vacuum Performances |

|

|

Main Chamber Vaccum |

< 9x10-3 Pa |

|

Sample Main Chamber Introduction |

< 5 min |

1

|

Fine-tune and create new materials surface characteristics by unprecedented milling precision and Isotope Selection seamlessly using the Wien filter in our ion implantation tool. |

2 |

Activitate dopants, repair unwanted lattice damage and immediately enhance materials properties by In-situ annealing capabilities. |

3 |

Ensuring a seamless transition in your experimental setups and maximize your research efficiency with switching between specie (N, Ar, O, He, Xe or gas mixtures) or (Au, Ge, Si), all from the same source. |

4 |

Ensure your resultats are free from photoluminescence artifacts, implantation irregularities and surface damage by excellent dose controlling in the system and removal of the neutral charge. |

5 |

Visualize and acquire clearer and more accurate resultats, by leveraging the advanced detection capabilities of YAP scientillators. |

6 |

Fine control of the acceleration voltage with a range of energy from 5 keV to 30 keV. |

7 |

Adjust precisely the dose prior to d by the sample prior to implantation using a new current measurement system. |

8 |

Locate the area of interest and avoid the ion implantation with a SEM in coincidence point with the FIB column. |

9 |

Your own experiments and analytical routines by utilizing advantages of ORSAY PHYSICS’s open hardware and software. |

.png)